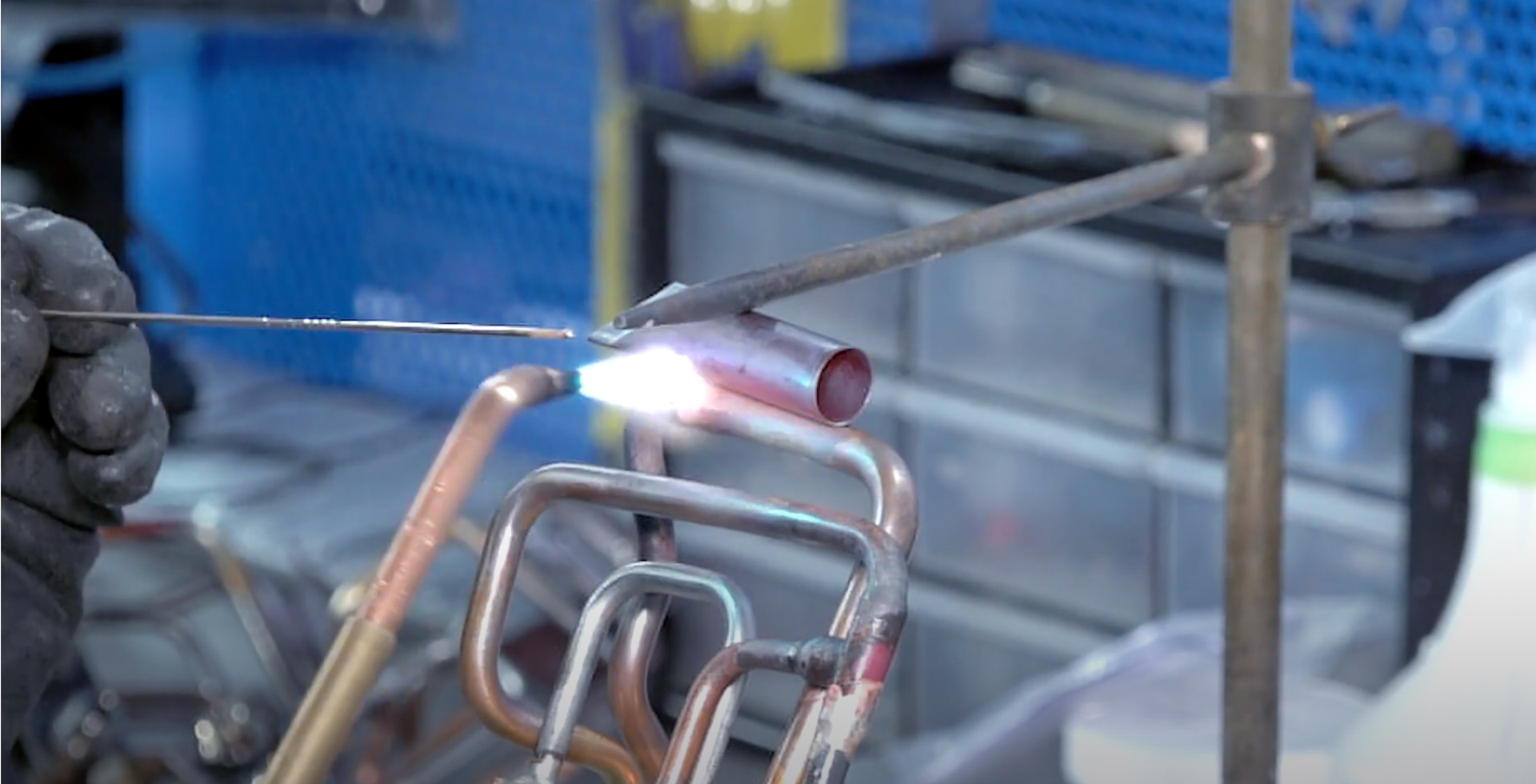

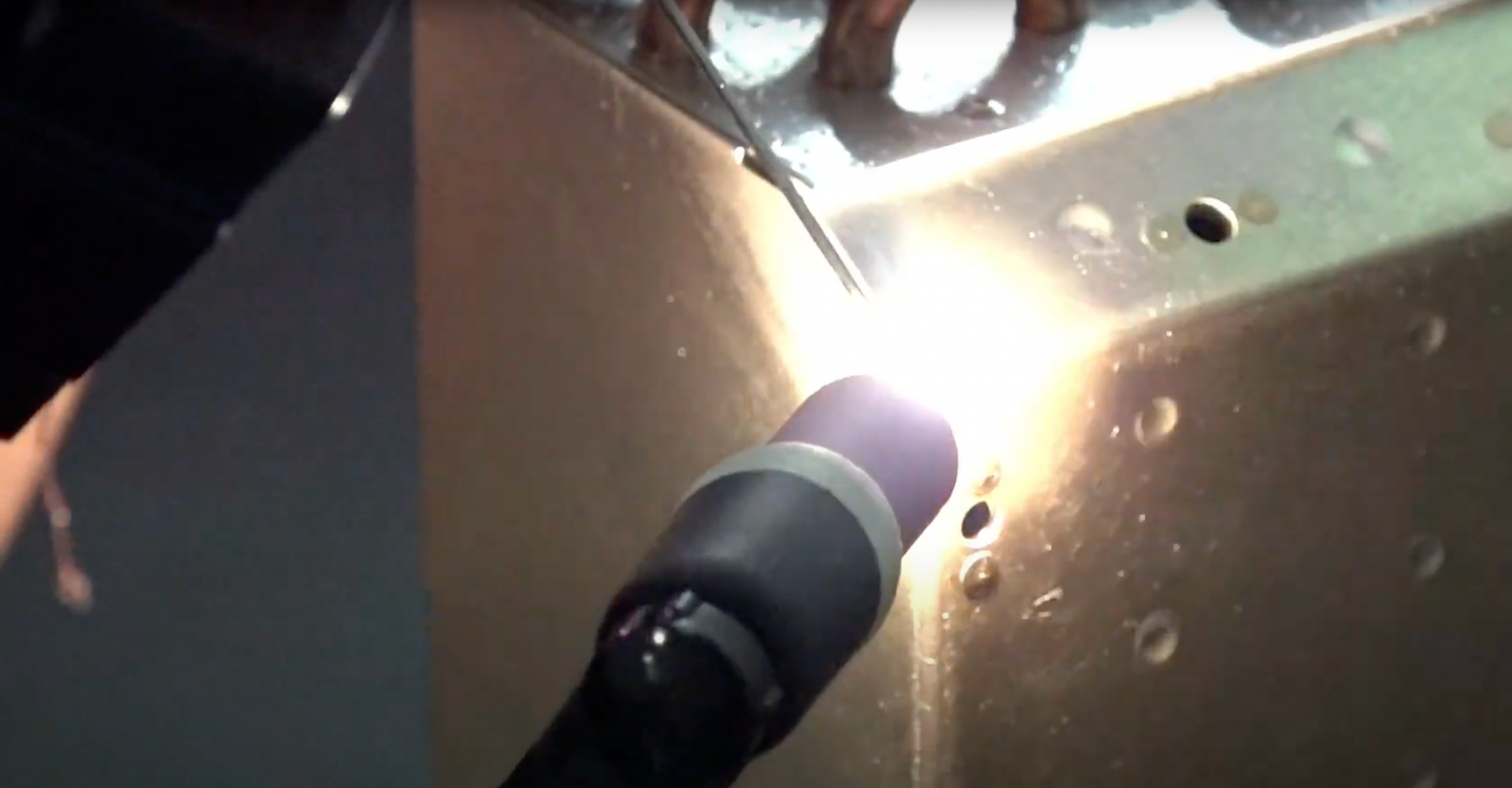

Kaizen Aero Manufacturing offers custom-built brazing services using different materials. Brazing uses fillers to join together different pieces to form a unit. It involves the use of high temperature to bond parts together. Parts brazed are close-fitted which results in a stronger joint compared to welding or soldering.

We use Oxy-Acetylene Torch Brazing method which is more flexible and typically used for more exacting operations which require a deft manual touch.